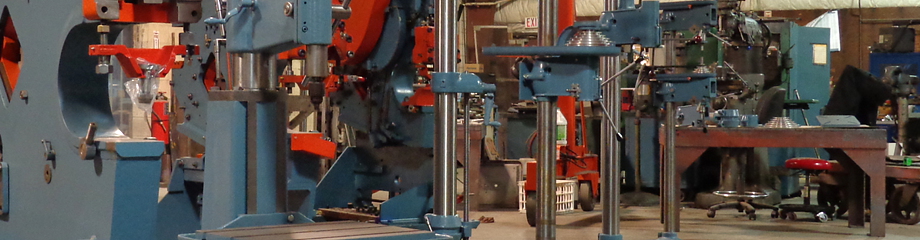

Drills

Heavy-Duty 1/2" Capacity Drill

Model No. 15 - Bench or Floor

-

Five-step V-belt pulley drive.

-

Six-spline alloy steel spindle with No. 33 Jacobs taper nose and 0-1/2" Jacobs chuck.

-

Full ball bearing construction with four permanently lubricated and sealed-for-life bearings including extra large bearing at spindle nose.

-

Large slotted table that can be tilted or swiveled.

-

Three-spoke feed handle that provides full 4-1/2" feed travel.

-

Clutch-type quill spring adjusts return speed and tension and compensates for tooling weight.

-

Adjustable motor bracket controls belt tension.

-

Machines are factory-assembled, factory-tested and shipped intact, ready for immediate use.

Accessories and Standard Modifications

-

Slow speed attachment - provides five normal spindle speeds in addition to five reduced spindle speeds at 4:1 reduction.

-

Legs for production bench models.

-

No. 2 Morse taper spindle nose adapter.

-

Head only and head, column & adapter.

Heavy-Duty 1" Capacity Drill

Model No. 18

Standard or production-type bench or floor models

- Five-step V-belt pulley drive.

- Six-spline alloy steel spindle with No. 3 Morse taper nose.

- Full ball bearing construction with four permanently lubricated and sealed-for-life bearings including extra large double-row thrust bearing at spindle nose.

- Large slotted table that can be tilted or swiveled.

- Three-spoke feed handle that provides full 5" feed travel.

- Clutch-type quill spring adjusts return speed and tension and compensates for tooling weight.

- Adjustable motor bracket controls belt tension.

- Machines are factory-assembled, factory-tested and shipped intact, ready for immediate use.

Accessories and Standard Modifications

- Slow speed attachment - provides five normal spindle speeds in addition to five reduced spindle speeds at 4:1 reduction.

- Legs for production bench models.

- No. 3 Jacobs taper spindle.

- No. 3 Morse taper to No. 2 Morse taper hardened reducing sleeve.

- 3/16" - 3/4" Jacobs chuck and arbor.

- 1/8" - 5/8" Jacobs chuck and arbor.

- Back spot facer.

- Head only and standard or production type head, column and adapter.